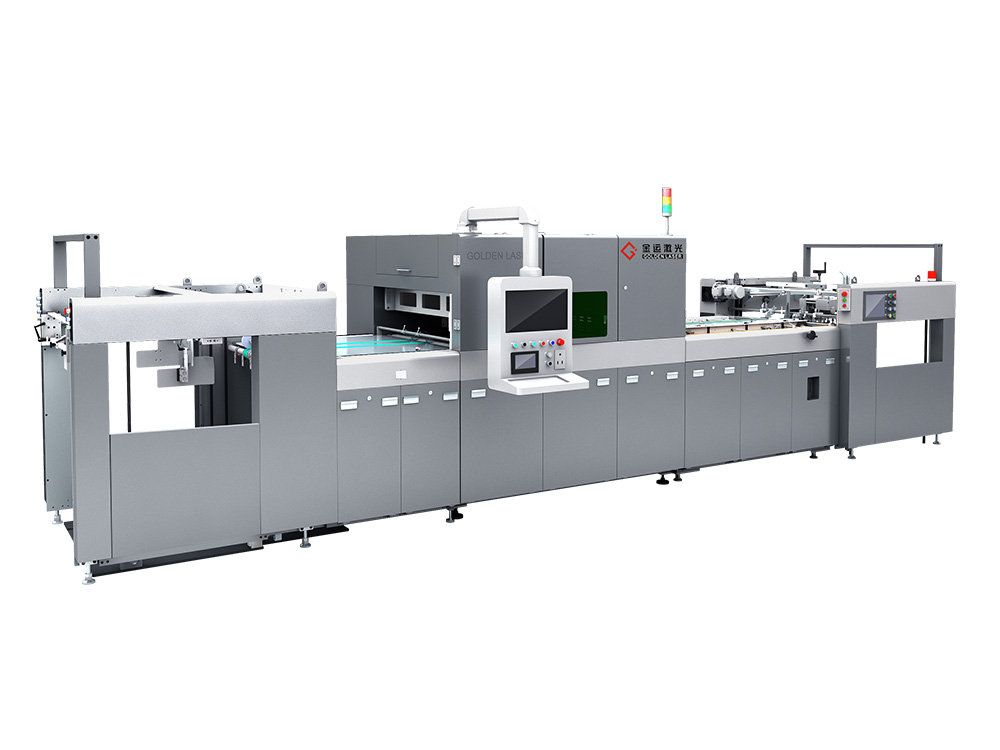

Sheet Fed Laser Die Cutting Machine

Model No.: LC1050

Introduction:

Sheet-fed laser die cutting system LC-1050 is specifically designed for high-volume processing of large-format, single-sheet materials offering long-term stable operation. Equipped with an oversized material storage system, it minimizes the need for frequent material reloading, significantly reducing manual operation time. This makes it ideal for continuous production of diverse product types.

LC-1050 Large-Format Sheet-Fed Laser Die-Cutting System

- Ushering in a New Era of Efficient, Flexible Digital Post-Press

LC-1050 Sheet-Fed Laser Die-Cutting Machine, a cutting-edge digital post-press solution designed to meet the modern printing and packaging industry's demands for high efficiency, precision, and flexibility. This system specializes in the batch processing of large-format sheet materials, enabling rapid and precise die-cutting, intricate cut-outs, scoring, and other processes for complex graphics without the need for conventional dies. It is the ideal choice for enhancing productivity and expanding your business capabilities.

Move beyond the limitations of traditional die-cutting. With its exceptional stability and automation features, the LC-1050 empowers you to effortlessly manage diverse production challenges, from short, quick runs to large-volume manufacturing.

Machine Features

• Optimized for Large Format, Stable & Reliable:

Designed specifically for single sheets up to 1050mm x 750mm, perfectly catering to mainstream size requirements in packaging, advertising, and more.

Robust construction and precision engineering ensure stable, continuous operation over extended periods, maximizing your production uptime.

• Extra-Large Capacity Feeder, Efficient & Worry-Free:

Equipped with a high-capacity automatic sheet feeder, holding more material to significantly reduce reloading frequency.

Drastically minimizes manual intervention, effectively saving valuable operator time and labor costs, leading to a smoother, more efficient production process.

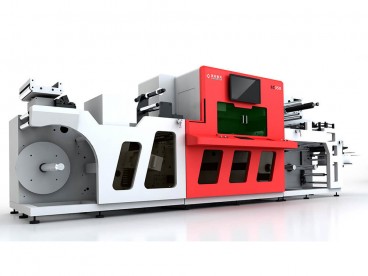

• HD Smart Vision System for Precision:

Integrates an advanced high-definition smart camera system for accurate identification of material edges and registration marks.

Perfectly supports seamless job changeovers and continuous production of multiple product types. Easily handles mixed jobs with different layouts or orders, meeting the demands for personalization, short runs, and multi-order flexible production.

• Fully Automated Workflow for Smart Production:

From the automatic feeder system and the bridge alignment system ensuring precise transport, to the fully automatic flying cutting process, the entire workflow is highly automated.

This minimizes human error and enhances processing consistency.