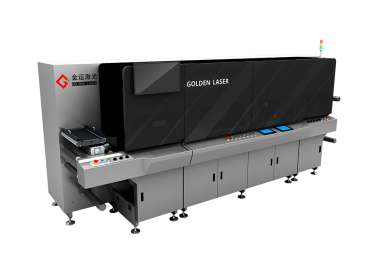

Roll-to-Roll and Roll-to-Part Laser Die Cutting Machine

Model No.: LC350F / LC520F

Introduction:

The Hybrid Laser Die-Cutting System can seamlessly switch between roll-to-roll and roll-to-part production modes, offering flexibility in processing label rolls of various specifications. It enables high-speed continuous processing, easily handling diversified orders and meeting a wide range of label production requirements.

Hybrid Digital Laser Die-Cutting System

Flexible & Efficient, Empowering Smart Label Production

The Hybrid Digital Laser Die-Cutting System is an advanced, intelligent solution specifically designed for the modern label processing industry. Integrating both Roll-to-Roll and Roll-to-Part production modes, this system easily adapts to diverse processing requirements. By utilizing high-precision laser cutting technology, it eliminates the need for traditional dies, enabling seamless job changeovers and flexible production. This significantly enhances both efficiency and product quality.

Whether for high-volume production or small-batch, multi-variety customized orders, this system delivers outstanding performance, helping businesses stay competitive in the era of smart manufacturing.

Key Features

The system supports Roll-to-Roll and Roll-to-Part cutting modes, allowing quick adaptation to different job types. Switching between production modes is fast and requires no complex adjustments, significantly reducing setup time. This enables seamless transitions between diverse orders and enhances overall production flexibility.

Equipped with an intelligent control program, the system automatically recognizes processing requirements and adjusts to the appropriate cutting mode. Its user-friendly interface makes it easy to operate, even for beginners, reducing the need for skilled labor. Automation throughout the process boosts productivity and helps factories achieve digital and intelligent manufacturing upgrades.

Powered by a high-performance laser source and advanced motion control system, the machine ensures a perfect balance between speed and precision. It supports high-speed continuous processing with clean, smooth cutting edges, delivering stable and reliable quality to meet the demanding standards of premium label products.

Digital laser die-cutting eliminates the need for traditional cutting dies, reducing tooling costs and maintenance expenses. It also minimizes downtime due to tool changeovers, improving production flexibility and significantly lowering total operating costs.

A camera system that:

• Detects Registration Marks: Ensures accurate alignment of the laser cutting with pre-printed designs.

• Inspects for Defects: Identifies flaws in the material or the cutting process.

• Automated Adjustments: Automatically adjusts the laser path to compensate for variations in the material or printing.

The system works with a variety of label materials, including PET, PP, paper, 3M VHB tapes, and holographic films. It is widely used in industries such as food and beverage, cosmetics, pharmaceuticals, electronics, logistics, and security labeling. Whether processing conventional labels or complex, custom shapes, it ensures fast, precise results.

Laser Die Cutting Advantages Over Traditional Die Cutting:

|

LC350F |

LC520F |

|

| Max Web Width |

350mm |

520mm |

| Laser Power |

30W / 60W / 100W / 150W / 200W / 300W / 600W |

|

| Laser Head |

Single laser head / Multiple laser heads |

|

| Cutting Accuracy |

±0.1mm |

|

| Power Supply |

380V 50/60Hz Three phase |

|

| Machine Dimensions |

4.6m×1.5m×1.75m |

/4.8m×1.6m×1.88m |

Golden Laser Die-Cutting Machine Model Summary

| Roll-to-Roll Type | |

| Standard Digital Laser Die Cutter with Sheeting Function | LC350 / LC520 |

| Hybrid Digital Laser Die Cutter (Roll to roll and Roll to sheet) | LC350F / LC520F |

| Digital Laser Die Cutter for High-end Color Labels | LC350B / LC520B |

| Multi-station Laser Die Cutter | LC800 |

| MicroLab Digital Laser Die Cutter | LC3550JG |

| Sheet-Fed Type | |

| Sheet Fed Laser Die Cutter | LC1050 / LC8060 / LC5035 |

| For Film and Tape Cutting | |

| Laser Die Cutter for Film and Tape | LC350 / LC1250 |

| Split-type Laser Die Cutter for Film and Tape | LC250 |

| Sheet Cutting | |

| High-precision Laser Cutter | JMS2TJG5050DT-M |

Materials:

These machines can handle a wide variety of flexible materials, including:

- • Paper: Labels, cartons, packaging.

- • Films: PET, BOPP, PP, Polyimide (Kapton), etc. Used for labels, flexible circuits, and packaging.

- • Adhesives: Tapes, labels, decals.

- • Textiles: Woven and non-woven fabrics.

- • Foils:

- • Laminates: Multi-layered materials.

Applications:

- • Labels: Producing custom-shaped labels with intricate designs.

- • Packaging: Creating custom packaging shapes and sizes.

- • Electronics: Manufacturing flexible circuits, components for sensors.

- • Medical Devices: Cutting materials for medical patches, devices.

- • Automotive: Manufacturing components for interior trim, labels.

- • Textiles: Cutting patterns for clothing, upholstery.

- • Aerospace: Cutting materials for aircraft components.

- • Prototyping: Quickly creating prototypes of new designs.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?